6 March 2024

Uwe Brodkorb, Project Manager at Scholpp:

"To mount the stairs safely, we needed totally reliable and easy to handle equipment that could be used in the smallest of spaces. Hiring the chain hoists from LGH was by far the safest and most cost-effective solution."

The challenge

With a height difference of 28 metres between the new underground and the existing overground station, steel stairs needed to be installed that passed through a mezzanine floor. In order to install the stairs, the Project Manager of Scholpp Group was faced with the dilemma that not only did the building site allow very little room for manoeuvre, the structure of the station was also unable to support heavy machinery. It was therefore necessary to find an alternative to the normally used truck crane.The solution

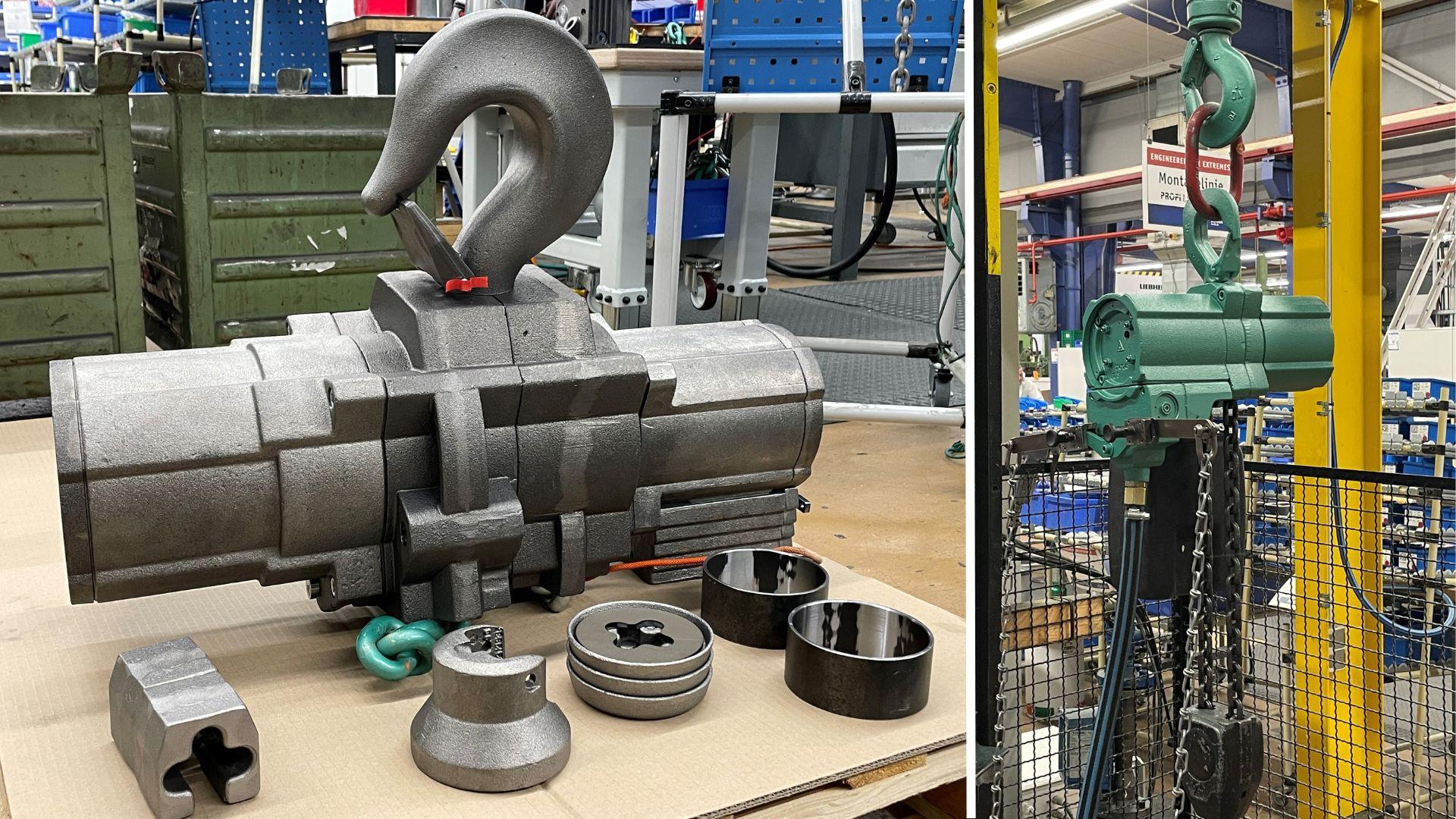

Mini hydraulic jacks were positioned on the mezzanine floor and rail-mounted to enable easy movement. Two 24-metre end carriages were mounted on the mini jacks and two LGH electrical chain hoists with a load capacity of 15 tonnes were fixed to each end carriage. Attaching the stairs at both ends enabled the installation engineers to control the necessary inclination. After suspending the first stairway from the first floor, the mini hydraulic jacks were extended to the next floor in order to compensate for the height difference and then used to mount the second stairway.Our equipment used for this project

|

24 May 2019

11 view(s)